Electric motors are critical components in industrial automation, providing the mechanical motion needed to drive machines, tools, and various equipment. Understanding the differences between AC (Alternating Current) and DC (Direct Current) motors is essential for selecting the right motor for specific applications.

Understanding Electric Motors

What is an Electric Motor?

An electric motor is a device that converts electrical energy into mechanical energy. It operates based on electromagnetic principles and is used in various applications, from small appliances to large industrial machines.

Working Principles of Electric Motors

Electric motors operate on the principles of electromagnetism. When electric current flows through a coil of wire, it generates a magnetic field. This magnetic field interacts with other magnetic fields (produced by permanent magnets or other coils) to create rotational motion. The fundamental difference between AC and DC motors lies in how the electrical energy is supplied and how the motors are designed to utilize that energy.

AC Motors

What are AC Motors?

AC motors are powered by alternating current, where the flow of electric charge periodically reverses direction. These motors are widely used in various industrial applications due to their efficiency and durability.

Types of AC Motors

- Synchronous Motors: These motors operate at a constant speed that is synchronized with the frequency of the AC power supply. They require an external power source to maintain the magnetic field.

- Induction Motors: The most common type of AC motor, induction motors do not require any external power source for their magnetic field. Instead, they rely on electromagnetic induction, where the rotor is energized by the rotating magnetic field created by the stator.

Applications of AC Motors

- Industrial Machinery: AC motors are extensively used in conveyor systems, pumps, fans, and compressors due to their robustness and efficiency.

- HVAC Systems: Heating, ventilation, and air conditioning systems utilize AC motors for fans and blowers.

- Pumps and Compressors: AC motors are commonly found in water pumps, refrigeration compressors, and other fluid movement applications.

Benefits of AC Motors

- Higher Efficiency: AC motors typically have a higher efficiency than DC motors, leading to reduced energy consumption.

- Durability: They are known for their long lifespan and lower maintenance requirements, making them ideal for continuous operation in industrial settings.

- Cost-Effectiveness: AC motors are generally less expensive than their DC counterparts, both in terms of initial investment and maintenance costs.

Challenges of AC Motors

- Speed Control: Controlling the speed of AC motors can be more complex and may require additional equipment such as variable frequency drives (VFDs).

- Starting Torque: Induction motors may have lower starting torque compared to some DC motors, which can be a limitation in specific applications.

DC Motors

What are DC Motors?

DC motors are powered by direct current, where the flow of electric charge remains constant in one direction. They are known for their simplicity and ease of control, making them suitable for various applications.

Types of DC Motors

- Brushed DC Motors: These motors use brushes and a commutator to deliver current to the rotor. They are simple in design and easy to control.

- Brushless DC Motors: These motors use electronic controllers to deliver current, eliminating the need for brushes. They offer higher efficiency, longer lifespan, and reduced maintenance.

Applications of DC Motors

- Robotics: DC motors are commonly used in robotic applications for precise control and movement.

- Electric Vehicles: DC motors are often employed in electric vehicles for propulsion and drive systems.

- Home Appliances: Various household appliances, such as vacuum cleaners and power tools, utilize DC motors for their operation.

Benefits of DC Motors

- Speed Control: DC motors offer excellent speed control, making them ideal for applications requiring variable speeds.

- High Starting Torque: They provide high starting torque, which is beneficial for applications that need immediate acceleration.

- Simplicity: The design and operation of brushed DC motors are straightforward, making them easy to implement and maintain.

Challenges of DC Motors

- Maintenance Requirements: Brushed DC motors require regular maintenance to replace brushes and clean commutators, leading to potential downtime.

- Limited Lifespan: The wear and tear of brushes can reduce the lifespan of brushed DC motors compared to AC motors.

Key Differences Between AC and DC Motors

| Feature | AC Motors | DC Motors |

| Power Supply | Alternating Current | Direct Current |

| Types | Synchronous, Induction | Brushed, Brushless |

| Speed Control | More complex; requires VFDs | Easy; can be controlled by voltage |

| Starting Torque | Generally lower in induction motors | High starting torque |

| Maintenance | Lower maintenance | Requires maintenance for brushed types |

| Cost | Generally less expensive | Can be more expensive depending on type |

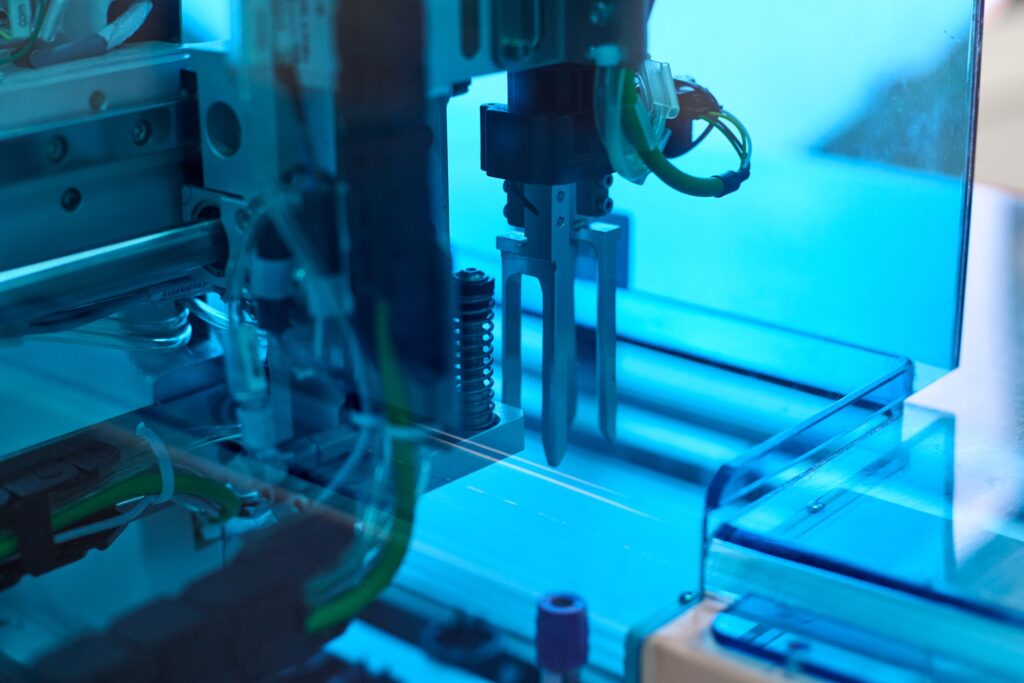

Use AC and DC Motors in Factory Automation

Understanding the differences between AC and DC motors is crucial for selecting the right motor for specific applications in factory automation and industrial processes. AC motors are known for their efficiency, durability, and cost-effectiveness, making them ideal for continuous operation in various industrial settings. In contrast, DC motors offer superior speed control and high starting torque, making them suitable for applications requiring precision and immediate acceleration.

As technology advances, the choice between AC and DC motors will continue to evolve, influenced by factors such as energy efficiency, application requirements, and the development of smart motor technologies. By understanding the unique characteristics and applications of AC and DC motors, industries can make informed decisions to optimize performance and efficiency in their operations.